Product: C-Coil annealing device working with protective gas

Type: AT-CCAD

Edition: 07/13

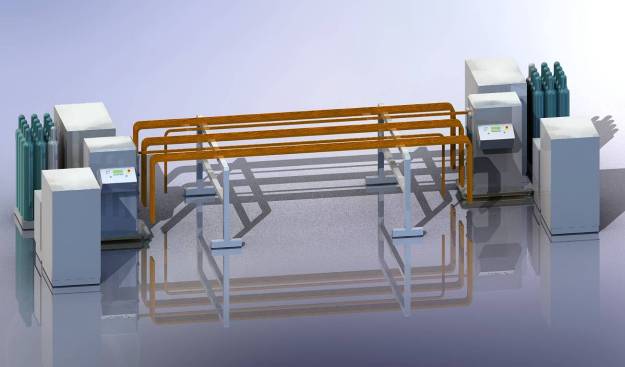

Product Specification C-Coil Annealing Device AT-CCAD 12-15

1. Description

This C-Coil annealing device works with protective gas.

The protective gas annealing has the advantage that it is a clean process. No finishing work is necessary.

After removing the coils from the annealing station, the ends of the C-coils are about 80°C or less. This depends on the cooling time.

2. Technical Data

CU strands: 28–40 mm x 6–10 mm

Inside bend radius (90°): 40 – 80 mm

Max. length of the bent arm: 1100 mm

Capacity: 2 bar ends / annealing unit

Cycle time: 4 to 5 minutes

Tightening: pneumatic

Annealing temperature: max. 800°C

3. Scope of supply

The C-Coil annealing device consists of:

- 1 or 2 pcs. annealing device including inductors (controlled by Siemens S7)

- 1 or 2 pcs. medium frequency generator with control interface

- 1 or 2 pcs. cooling unit for inductor

- 1 or 2 pcs. water cooling system

To be supplied by the customer:

Inert gas (CO² or equivalent)

4. Operation

Two pieces of copper bars (c-shape) are inserted into the annealing device. When they are in the correct position – optical display – the annealing process begins. During the whole process, CO2 is supplied.

After shut down of the MFG-system, the bars are cooled down to a temperature of approx. 80°C with the aid of a coolant (elapsed time adjustable). After the end of the cooling down (optical display) the bars can be taken out of the device. The correct heating period and power must be established through preliminary tests.