Product: Roebel bar inter turn strand tester / Teilleiter Test Maschine

Type: AT-ITST

Edition: 01/22

Product Specification Inter Turn Strand Tester AT-ITST

1. Description

The Interturn strand tester is developed for the measurement of straight bar short circuits after consolidation of the straight bar section. The AT-ITD is designed for two-rowed bar types.

2. Technical Data

Width: approx. 800 mm

Length: approx. 1000 mm

Height: 1220 – 1620 mm

Weight: approx. 320 kg

Max. no. of strands: variable up to 2 x 50 = 100 strands per bar

Strand cross-section max.: 3,2 x 15,0 mm

Strand cross-section min.: 1,0 x 5,0 mm

Testing voltage: 110 – 350 VAC 50Hz

Failure criterion: Insul. Resistance: 10 kΩ ± 1000 Ω

Power supply: 230 VAC N PE

Pre-Fuse: 16 A

3. Scope of supply

The AT-ITD consists of:

- Frame (adjustable in height)

- Testing equipment head

- 2 separators for expanding the strands

- Electric control cabinet

- Touch screen including software for convertion and evaluation of the data

4. Operation

The strands must be spread out on a separator. This must be done on each side of the bar. (On the measurement side and on the other side – all strands are isolated from each other). One side of the bar is inserted into the test appliance head. The upper part of the test appliance head will be closed manually. By doing so, the strands are contacted on both sides. Now the test program is ready to start. The measurement works automatically.

Each strand is contacted with two separate measurement pins. The first pin checks the contact between the strand and the second pin. With this method it is guaranteed that both pins are in contact with each strand. If there is no contact a message will appear on the PC screen.

The second pin is the measurement pin and brings the measurement voltage into the strand. If there is contact – insulating defect – the defect will be registered and recorded.

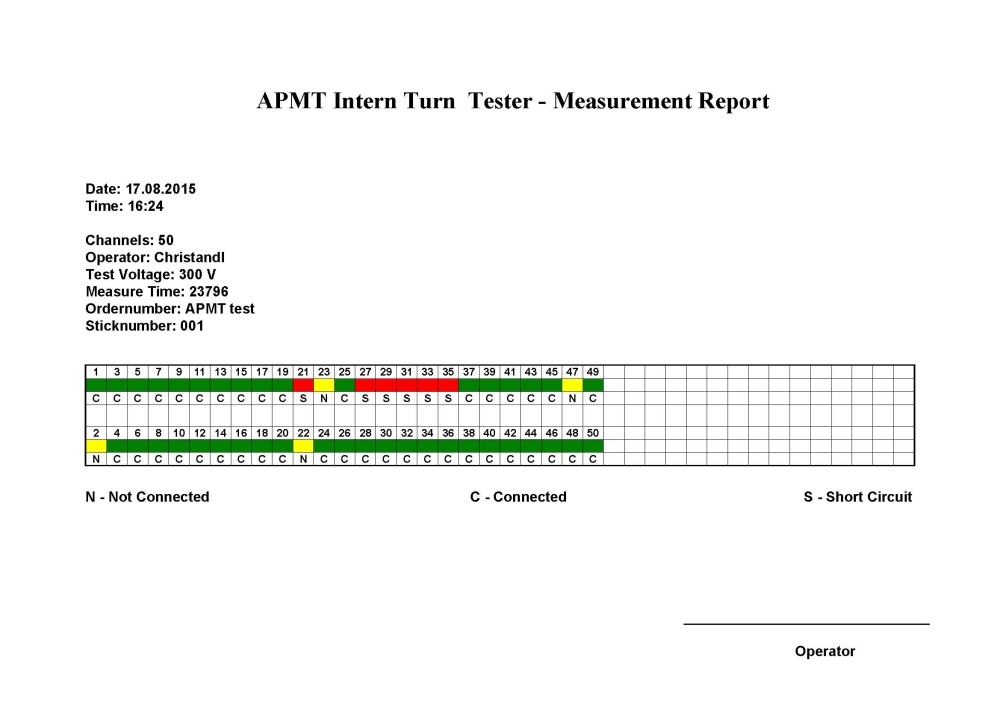

Each strand is tested in relation to the next one. The test results are reported in a report file (PDF). This file can be viewed on the PC screen and can also be saved electronically. Each bar could get a number, and with that number the file containing the results will be saved. In this way it is possible to identify each bar with the file containing its measurement results.

A network interface is installed.